Location: Southgate, CO

Client: Southgate Water & Sanitation Districts

Carylon Operating Company: Ace Pipe Cleaning

Services Performed: Water Main Inspection & Leak Detection

The project consisted of selecting pipes leveraging existing GIS data and data from past breaks to determine optimal test segments. Segments were selected and mapped utilizing ESRI ArcGIS and organized an efficient inspection schedule from the GIS maps. A site reconnaissance team verified asset locations and accessibility and testing was conducted utilizing electromagnetics technology. Testing was conducted on DIP and AC pipe primarily. Approximately five miles were surveyed.

As part of this contract, acoustic testing was performed to determine average pipe wall thickness of a small, but selective, sample of water distribution assets ranging from 6-12″ in diameter of various materials-of-construction. A strategic and comprehensive plan was implemented to ensure that the test group represented the materials and ages of the pipes in the system and selected sites met the stringent criteria required to ensure optimal results using non-invasive technologies. Available methods and technologies to verify the acoustic results that did not require excavation along with the collection of coupon samples, and laboratory testing such as petrographic and metallurgical analysis depending on the pipe material were performed. A plan was also developed to verify the results of the acoustic testing.

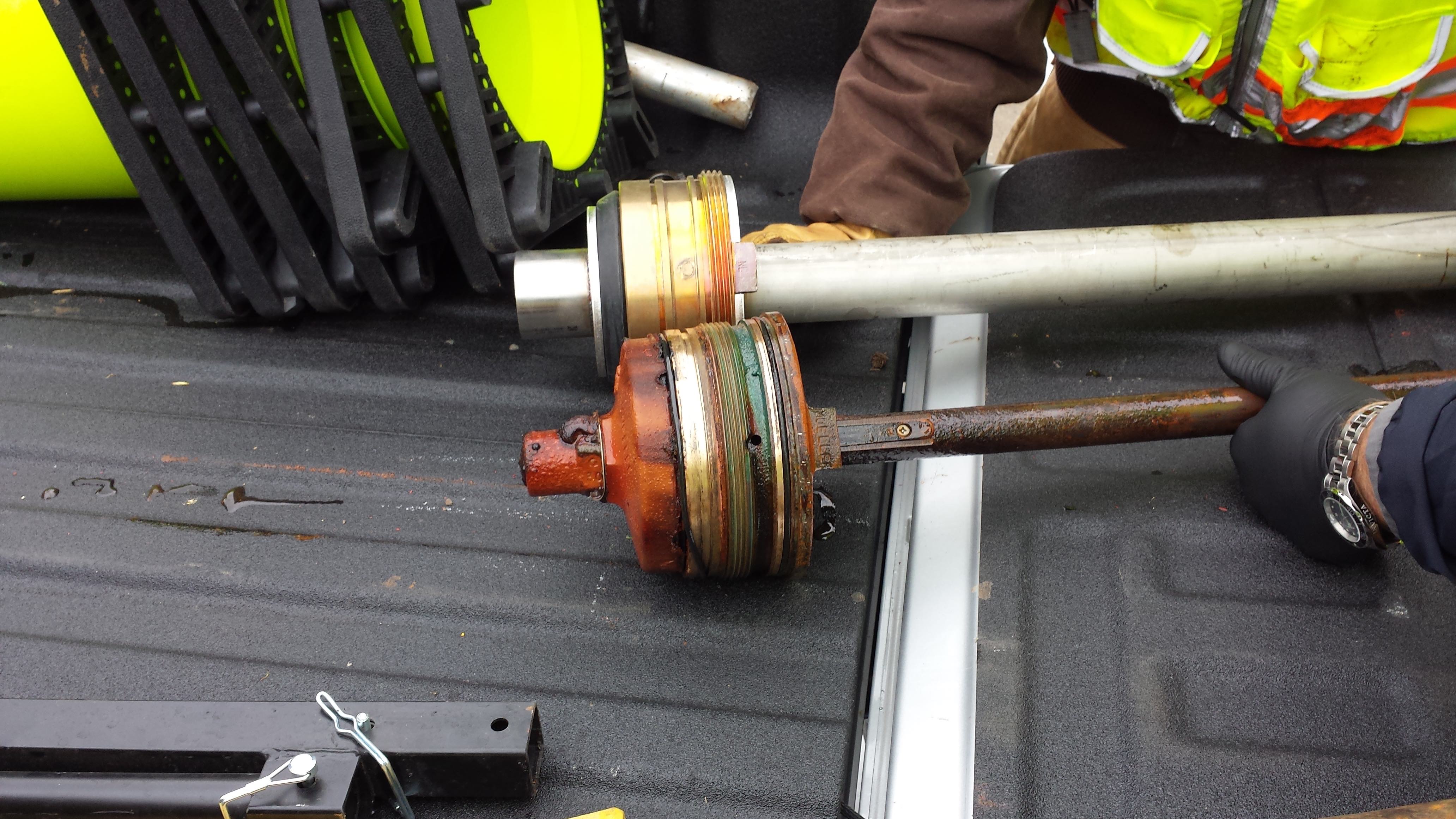

Ace Pipe Cleaning also provided hydrant disassembly labor and general logistic support to the project. Ace further supported the team with an expansive repertoire of hydrant repair and rebuild experience throughout the US. This experience proved invaluable in the careful disassembly and reassembly of dry barrel hydrants to prepare and return to service testing sites.