Multi-sensor inspection (MSI) refers to the collection of data from multiple sensors on one robotic platform in one pass through a pipeline.

Using this technology, our technicians can collect and process data on internal pipeline conditions, including debris level, ovality, H2S corrosion, lateral location, and damage without requiring flow diversion, flow interruption, or manhole ring removal.

Multi-Sensor Inspections (MSI) Transporter Platform

Our LIDAR/SONAR/HDCCTV PLATFORM does the work when floating is not an option. The setup, a live feed- full MSI unit mounted on the 4 wheeled drive crawler. The remote elevator lift can raise and lower the LIDAR and HV Camera as needed based upon flow or other conditions, while the SONAR head stays below the flow. The crawler setup is very effective in 24” to 112” pipe.

MSI Benefits and Return on Investment

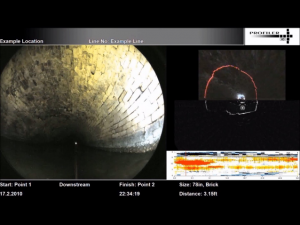

Pictured here is a screen shot of a post-processed inspection data. On the left is the HDCCTV video of the pipe the area below the red Laser ring at 8 and 4 o’clock is the waterline, the white portion of the circle is the submerged Sonar unit as it performs the underwater Sonar scans and imaging. The top red line is the Laser ring projected on the pipe walls. Four (4) HD cameras monitor the image hundreds of times a minute to document any anomalies or deviations. A 360-degree circle is created by the Laser ring above the flow and the Sonar ring below the flow, these images are heavily analyzed to record every anomaly within 1% of the pipe diameter since installation.

Any deviations are scored based upon their significance. A cumulative score of the new “shape” (pictured here as several rows of missing bricks) creates a deterioration rate over time. This can be one factor to consider in the development of a “Remaining Useful Life” value of that asset. The inspection data reporting generates the pipe’s Corrosion values, debris quantities, flow depths, measured pipe size and the current ovality deflection percentages. This information can quickly be utilized for pipe cleaning costs, disposal costs, and to minimize environmental hazards, bypass pumping costs as a consequence of potentially avoidable collapses in the pipeline.

Want to learn more about Ace Pipe’s Multi-Sensor Inspections? Check out this article.